Food Waste Pre-Treatment!

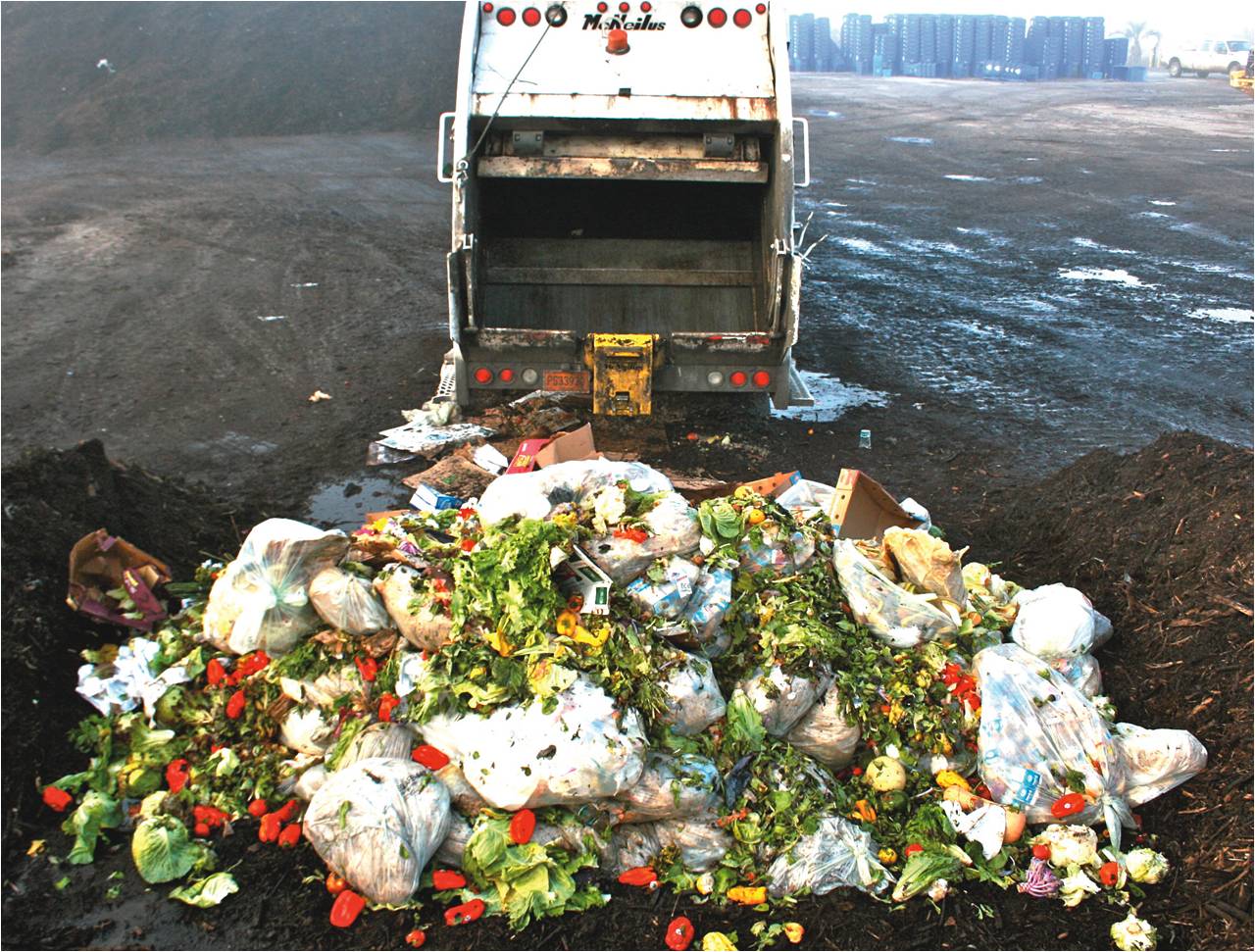

Effective food waste pre-treatment is essential to ensure efficient performance of the digestion process. These wastes need to be free of contamination like plastic and other packaging materials, cardboard, metal pieces, wood particles, glass pieces etc., and then they need to be converted into a homogeneous organic mixture suitable for anaerobic digestion process.

Depending on the level of impurity and sources of the products, food waste/OFMSW (organic fraction of municipal solid waste) feedstock may be required the following pre-treatment technologies for the purification:

- Receiving and manual sorting

- Bag opener

- Shredders

- Screw Cutter

- Milling

- Rotating Drums

- Rotating Trommels

- Screens

- Magnetic separators

- Sterilizer

- Pulper

- Hydrolyser

- Homogenizer

Food Waste Pre-treatment Technologies and Technology Suppliers:

BioPrePlant® System:

The BioPrePlant® System is designed for food waste pre-treatment. BioPrePlant System also has a customized automation and control system to reduce operator interventions. The BioPrePlant® System has the following stages and components as per manufacturer document (source: http://www.biopreplant.com/Resources/BioPrePlant-System_Folder_EN.pdf):

Reception

BioPrePlant-System’s food waste reception is a multi-waste system where

food waste from households, supermarkets, restaurants and other wastes are

collected together without any sorting or de-packaging. The mixed food waste is

then automatically transported for further treatment and separation.

BioPreCrusher

In the next stage of the process, packaging bags and other food

containers such as tins are opened and ferrous metals are removed by using the

BioPreCrusher machine. The BioPreCrusher is very important part of the

BioPrePlant-System as it prevents undesirable metals and other larger objects

from entering into the process. The BioPreCrusher contains a crusher, a

transport conveyor and a magnet. In this step, larger non-crushable objects are

automatically discharged from the machine as well.

Material Transportation

Material transportation in a BioPrePlant-System is conducted via spiral

conveyors or pumps to ensure a clean and efficient system. As per manufacturer

claims, it also minimizes spillage and leakages during operation that improves

the overall working environment and surroundings.

BioSep® Stage 1

The next stage is a patented process machine called BioSep. It is

dedicated to separate plastics and packaging material from mixed food waste. This

machine separates, washes, and dries plastics and food packaging material and

discharges them out of the machine as reject.

BioSep® Stage 2

BioSep Stage 2 has the similar function as BioSep Stage 1. The

difference is that BioSep Stage 2 has a finer masking of the sieve that ensures

separation of even small pieces of plastics and packaging material that wasn’t

separated in BioSep Stage 1 in order to utilize the resource in food waste

optimally.

Biosubstrate

A biosubstrate suitable for

anaerobic digestion is the end product from a BioPrePlant-System. Manufacturer

claims that the particle sizes of the organic material, and the amount and

sizes of the remaining impurities are well within the technical and

environmental requirements for biogas production.

Sysav’s Pre-treatment Plant for Food Waste

In Sysav Biotec’s

pre-treatment plant, food waste is converted into pumpable, viscous slurry as

the end product. Sysav’s pre-treatment plant can receive three type of food

waste and they receive pre-treatments accordingly. Discover more on Sysav food waste pre-treatment.

Go back to Anaerobic Digestion Pre-treatment Home!

Go back to The Eco Ambassador Home!

Total Visits to Site: