Biogas Plant

Although

a biogas plant/ an anaerobic digestion plant is a 200 years old technology, it

is getting popular recently because of its ability to generate biogas, an

alternative fuel. One of the most advantageous point of this system is its

ability to produce energy from waste products such as sewage sludge,

agricultural residues, food wastes and different industrial and municipal waste

products. More over, it not only creates valuable energy products at the end

but also treat or sanitize those wastes for safe disposal.

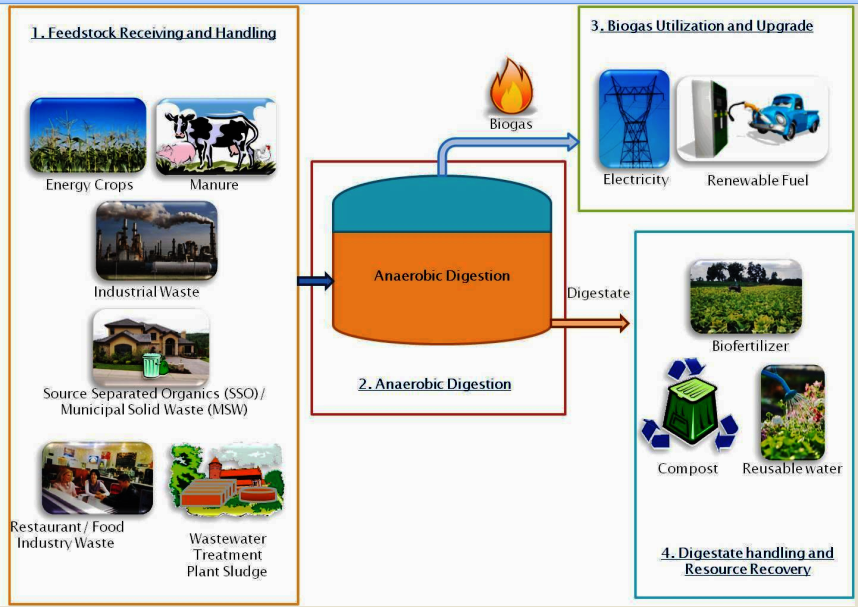

Major Component of a Biogas Plant:

A biogas can be divided into the following four major section sections:

- Feedstock receiving, handling and storage area

- Anaerobic digestion tanks

- Biogas capture, storage and treatment equipment

- Digestate handling and resource recovery (if desired)

Planning and Design consideration for a biogas plant:

The scale of a biogas plant may differ based on the type and quantity of the wastes it is going to treat. The basic consideration of planning a biogas plants are as follows:

Feedstock receiving, handling and storage area:

Different wastes are suitable as a feedstock for a biogas plant. But the feedstocks should be chosen based on their availability, quality and quantity. Also, if multiple wastes are digested together then different criteria should also be considered before co-digestion.

For multiple wastes, multiple wastes multiple receiving and storage may require. For example, for liquid wastes like FOG (Fat, Oil and Grease) a heated tank is required while for solid and semi-solid wastes concrete basin or stainless steel pits should be preferable.

Also, transporting and receiving feedstocks at the plant should be considered. In addition, some feedstocks need additional treatment like grinding, chopping, sorting, pasteurizing, hydrolyzing etc. So, adequate pre-treatment technology should also be considered if preferable and affordable.

Anaerobic digestion types and technology:

For designing a biogas plant different important anaerobic digestion process parameters should be considered. Also for running an anaerobic digestion plant temperature is an important issue which should also be decided.

There are various anaerobic digestion types and technology available and based on the feedstocks type the most suitable one should be chosen.

There are different shapes of anaerobic digestion tanks available. Most common shape for anaerobic digestion tanks is cylindrical (for United States it is shallow and cylindrical one). The egg-shaped digester is more recent one – mostly adopted in Germany and growing popularity in the United States. Digester tank mixing is also an important issue. Digester mixing System can be divided into tree categories - Gas injection mixing, mechanical mixing and Pump Mixing. Currently mechanical and pump mixing are most common and preferable ones.

Biogas capture, storage and treatment equipment:

Biogas storage can be done at the same digestion tank or a separate tank with a fixed or floating roof system. Detailed on biogas cleaning and treatment is discussed in the following page:

Biogas Cleaning and Treatment.

Other auxiliary equipment for biogas safety and handling are gas safety equipment like Pressure relief valves, vacuum relief valves, flame traps and automatic safety shutoff valves etc.; gas monitoring equipment or gas meters and a waste gas flare.

Digestate handling and resource recovery:

The detailed of digestate

handling and resource recovery are detailed in this page.

|

Advanced Processes and Technologies for Enhanced Anaerobic Digestion Most Recent Advances in Anaerobic Digestion Inside One Document! |

Other Considerations:

Projected plant income and cost

- Plant capital and operating cost

- Possible grant and financing options

- Comparing income/benefits vs. cost of running the plant

Plant Location

- Transportation and waste receiving/disposal convenience

- Heat and electrically demand and usage in the surrounding community

- Aesthetic acceptability

- Local regulations and laws

- Applicable planning and construction laws, waste permit etc.

- Suitable major and auxiliary equipment and complete plant lay out and design

- Consider/contact similar reference plants

- Considering/comparing different suppliers

- Warranties, after sale care, training and maintenance etc.

- Electrical standard and connection of the process equipment

- Civil engineering construction of tanks and buildings

Plant operation and Maintenance

- Who will run the plant – operator hours and number of operators

- Running hour and associated cost for each process equipment

- Data collection and monitoring the performance

- Safety

planning and measurement

More Information on Biogas and Biogas plant in Canada

Biogas and Anaerobic Digestion Basics

Go back to The EcoAmbassador Home!

Total Visits to Site: