Anaerobic Digestion Pre-treatments-

Sorting, Separation and

Homogenization of Waste

For any anaerobic digestion feedstocks, the first step of pre-treatment is to remove non-biodegradable and inert materials that can negatively affect downstream processes and equipment.

Undesirable items in the feedstocks such as bigger piece of paper, plastic, clothing, metal pieces, rocks etc. can be manually sorted at the receiving station of the treatment plant. Then, if required, the feed stream is send to the mechanical sorters for further separation of contaminants. Feed stream like manure only require grit and sand removal while feed stream like municipal solid waste requires much more complex treatment with multiple separation units working in series.

Some Anaerobic Digestion Mechanical Pre-treatment Units

Some of the mechanical separation equipment for pre-treatments of contaminated feedstock are as follows:

- Stone trap

- Float trap

- Grit tank

- Screens

- Rotating Trommels

- Magnetic separators

- Floor

Scraper

Some commercially available separation units are:

- Horizontal Separator (Hybag)

- Vertical Bioseparator (Doda)

- Hammer Mill Separator (Wackerbauer)

- Vertical

Chain Mill + Piston Press (FITEC)

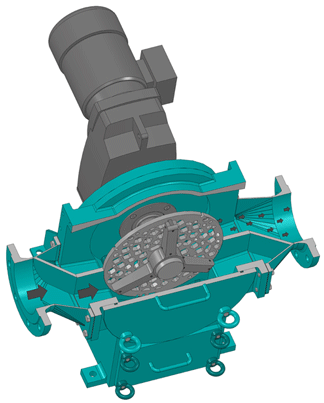

A Multichopper unit by Börger

Source: http://www.boerger.com/en_US/products/macerating-units/multichopper/operating-principle.html

Sometimes feedstocks need to be homogenized before feeding it to the digester to ensure an efficient process performance and smooth operation. Feedstocks like energy crops (grass silage etc.) are usually chopped to a uniform size. Other feedstocks may be converted to smooth slurry for feeding and mixing conveniences. Equipment involved in the homogenization phase may involve the following:

- Shredders

- Screw Cutter

- Milling

- Rotating Drums

Commercially available homogenisation systems utilize mixing and coarse grinding actions with augers and shaft based grinders. Key technology suppliers include Vogelsang (www.vogelsangusa.com/products/digester-feed-products) and Borger (www.boerger.com) and some of their chopping, grinding and feeding technologies are:

- Vogelsang Energy Jet solid material feeder

- Vogelsang Quickmix system

- Vogelsang BioCut

- Borger Multicrusher

- Borger Multichopper

- Borger Powerfeed SSR

Feedstocks homogenization sometimes also includes addition of water to reach desirable dry matter content. It is important to maintain the optimum solid content inside the digester to prevent clogging, settling or formation of floating layers.

Go back to Anaerobic Digestion Pre-treatment Home!

Go back to The Eco Ambassador Home!

Total Visits to Site: