Solid Anaerobic Digestion Technology

Low and high solid anaerobic digestion are ways to categorized anaerobic digestion technology based on their ability to handle solid content of the different feedstocks or feedstock's mix.

New and emerging feedstocks like organic fraction of municipal solid waste (OFMSW), energy crops, food waste etc., have been introduced to the anaerobic digestion technology. The concept of co-digestion or digesting two or three feedstocks types together is also getting popular. As a result the type and solid content of the feedstock mix is getting crucial for selecting the anaerobic digestion process and technologies. Based on the ability to handle the feedstocks solid content, anaerobic digestion technology can be broadly divided in to two categories-

- Low Solid/ Liquid Phase/Wet Digestion Technology

- High

solid/Solid State/ Dry Digestion Technology

Low Solid Anaerobic Digestion (Wet/Liquid Phase Anaerobic Digestion)

Anaerobic digestion systems

that can handle input solid content only up to 15% are known as low solid

anaerobic digestion. These are the most common type of anaerobic digesters

available. They are also called wet digestion or liquid-phase digestion. The

types of feedstocks treated by this group of digesters are wastewater sludge,

industrial wastewater, manure, food waste slurries, FOG etc.

High Solid Anaerobic Digestion (Solid State/Dry Anaerobic Digestion)

Anaerobic digestion systems that can handle higher solid content

(>15%) are known as high solid digestion or dry digestion. Dry digestions

are suitable to handle waste at high solid loadings as well as lingnocellulosic

biomass such as silages of corn, grass, rye etc.;

coarsely shredded MSW, residential food waste along with lawn and yard waste

etc. This type of digesters usually produce end product with higher solid

content and consume less energy for heating. But they require longer retention

time and additional equipments for mixing and material flow on the output side.

The high solids anaerobic digestion that is designed for pumpable high solid

feed like wet food waste slurries (usually 15-35% solid content) are further

known as wet high solid or dry pumpable digestion.

Example of High Solid Anaerobic Digestion Technologies:

DRANCO Anaerobic Digestion Technology

( http://www.ows.be/household_waste/dranco/)

The DRANCO anaerobic digestion technology by Organic Waste Systems (OWS) is a patented process. The three main characteristics of DRANCO are its vertical design, high-solids concentration and the absence of mixing inside the digester. DRANCO digestion is often applied to mix waste or residual household waste or organic fraction of municipal solid waste (OFMSW), source separated organics, yard and food waste. The plant can operate at dry matter content inside the digester of up to 40 %. Some characteristics of this technology as reported by OWS are:

- High rate dry digestion

- Vertical digester with feeding at the top and removal from the bottom

- Single phase digestion with recycling

- Option for thermophilic or mesophilic operation

- No mixing, stirring or gas injection in the digester

- Single digester with a capacity up to 60,000 tons per year of household organic waste.

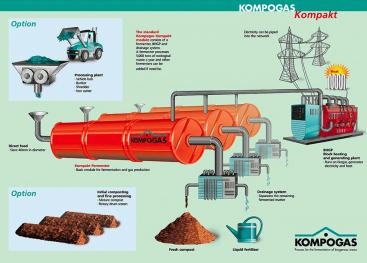

Kompogas Anaerobic Digestion

(http://www.hz-inova.com/cms/wp-content/uploads/2015/06/HZI_Kompogas_10_engl_RZ_3_WEB.pdf)

The Kompogas is a patented dry anaerobic digestion process for

organic waste. The process uses a continuously

feed horizontal plug-flow digester. The feed system automatically conveyed the

feed to the digester and process water is added inside the digester to maintain

the optimum ratio. The digester has a low speed agitator inside for mixing and

preventing sedimentation. The temperature of the process is thermophilic

operating at 53-55 0C. The average feedstock moisture content is

around 75% and the retention time inside the digester is approximately 14 days.

Schematic description of the Kompogas high solid dry Anaerobic Digestion- Source: OSTREM (2004)

(Image courtesy: http://www.sswm.info)

GICON High Solid Anaerobic Digestion

(http://www.gicon-engineering.com/en/about-us.html)

GICON is a two-stage dry-wet anaerobic digestion process and operates in

batch mode. The technology was developed, tested and commercialized in Germany

by Grossmann Ingenieur Consult GmbH (GICON). The Harvest Energy Garden located

in Richmond, BC, Canada is based on this technology and is owned and operated

by Harvest Power Canada Ltd. This is the first industrial-scale high-solids

anaerobic digestion (HSAD) plant in Canada and is also one of the largest HSAD

plants in North America. The plant processes approx. 30,000 t/a of combined

food waste and yard waste and produces approximately 770 kW of electrical

energy (www.gicon.de/uploads/tx_sbdownloader/Factsheet_Vancouver_EN.pdf).

Eisenmann High Solids Anaerobic Digestion System (http://www.eisenmann.us.com/biogas-and-anaerobic-digestion/anaerobic-digestion-technology)

Eisenmann has a modular high solids anaerobic digestion system. The system is typically based on a two-stage process with a primary and secondary digester. The main characteristics of this process are:

- Continuously mixed plug-flow process

- Enclosed system with potential odor prevention

- Modular design

The BIOFerm™ Dry Fermentation System

(https://www.biofermenergy.com/ext-dry-fermentation)

The BIOFerm™ is a batch type dry anaerobic digestion system that operates in the mesophilic temperature range. It is well suited for solid waste materials with a solids content of 25-35%.

BIOFerm plants consist of multiple concrete garage style digesters that can be sealed gas-tight. Front-end loaders load feedstocks into these chambers where they get digested for an average of 28 days. The digesters are heated through in-wall radiant heat and through the percolate, which is sprayed onto the feedstocks using the over-head sprinklers. Inside the digester, feedstocks remain still. But the percolate and water produced are continuously collected through floor drains and re-circulated. The BIOFerm™ Dry Fermentation system is suitable for municipal organic waste including yard waste.

Discover more on Anaerobic Digestion Types

Go Back to The EcoAmbassador Home.

Total Visits to Site: